Table of Contents

Batch picking increases picking efficiency—but it also creates a sortation requirement. Once you’re picking multiple orders at once, automated sortation becomes essential to keep pace and avoid downstream congestion.

But which sortation system should you choose? Well that depends.

Sortation systems generally fall into three categories: loop sorters (tilt-tray, crossbelt), linear sorters (sliding shoe, pop-up wheel), and robotic sortation (AMR-based).

- Loop sorters deliver the highest throughput for operations with consistent volumes

- Linear sorters balance capacity and footprint for mid-range facilities

- Robotic systems offer flexible scaling for operations with seasonal variation or growth uncertainty

The sortation market offers three main architectures, each with different trade-offs. Your best fit depends on your volume pattern, facility layout, and capital availability. Understanding when each makes sense saves you from overbuilding for uncertain futures or underbuilding for certain growth. Here’s the high level breakdown:

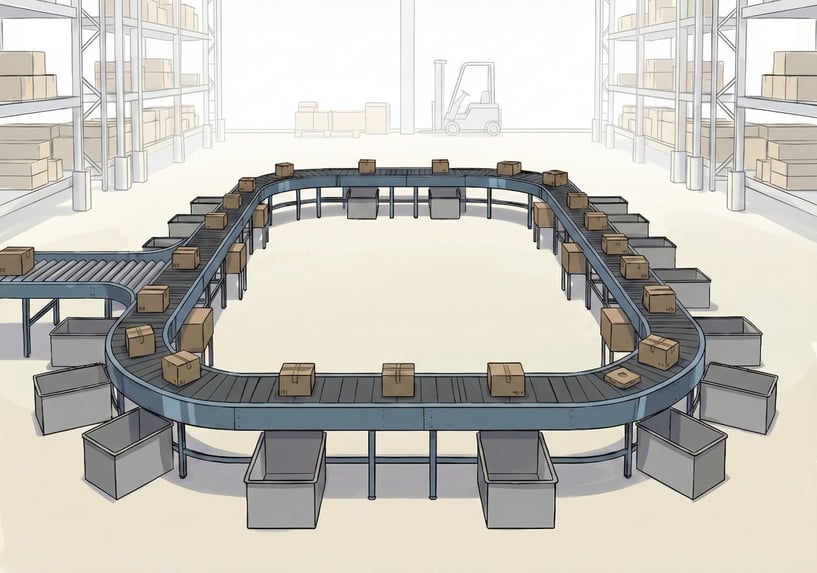

Loop Sorters: High Capacity in Continuous Circuits

Loop sorters run items around a continuous track, with carriers that pick up a product and ride the loop until they reach the right drop-off point.

Types of Loop Sorters |

Common Use |

Throughput |

Item Type |

|

Tilt-Tray |

E-commerce, Apparel, Parcel |

High |

Wide mix, polybags, smalls |

|

Cross-Belt |

E-commerce, Parcel, Postal |

Very High |

Semi-wide mix |

|

Bomb Bay |

E-commerce, Apparel, Mail |

High |

Small, flat items |

|

Pouch Sorter |

E-commerce, Returns |

High |

Single items, apparel |

Tilt-tray sorters use individual trays mounted on a continuous loop of carriers. As items travel on their assigned tray, the system triggers the tray to tilt at the right moment, using gravity to gently slide products into their destination chute. This approach handles diverse products well because the tilting motion works with almost any shape that fits on the tray. Throughput ranges from 8,000-43,000 units per hour with high accuracy across 100+ destinations.

Cross-belt sorters take a different approach. Each carrier on the loop has its own powered conveyor belt running perpendicular to the direction of travel. When a carrier reaches its destination, the belt activates and moves the item left or right off the sorter. This active discharge handles the widest product range, from 0.4 lbs fragile items to 165 lbs heavy parcels, processing 15,000-80,000 units per hour. They cost the most but deliver maximum throughput.

Bombay sorters work by opening trap doors built into the bottom of each carrier. When an item reaches its destination, the doors release and the product drops through onto a chute or conveyor positioned below. The vertical drop makes these ideal for small, flat items like apparel, mail, and polybags that can handle the short fall without damage.

Pouch sorters suspend fabric pouches from an overhead track system. Items ride in the pouches as they move along the track, and the pouches open at programmed points to release items into their destinations below. The soft fabric handling makes these particularly good for apparel returns and bagged items that might get damaged by harder sortation methods.

Loop sorters are fixed infrastructure requiring 12-18 months for implementation and investments from $2-10 million depending on capacity. Due to requiring heavy machinery that can be difficult to scale, it’s important to design them with future growth in mind and achieve the lowest per-unit cost at very high sustained volumes. The circular configuration requires significant floor space but maximizes destinations per square foot of loop.

Best for: Operations processing 8,000+ units per hour with consistent volumes, facilities with open floor plans that accommodate circular layouts, single-tenant operations with 10+ year facility commitments, and budgets supporting $2-10 million investments.

Challenges: Limited product range, poor handling of fragile items, and scalability issues when destinations exceed 200. Requires fixed infrastructure that can limit the ability to reconfigure and scale the system.

Linear Sorters: Straight-Line Efficiency

Linear sorters move items along straight conveyor paths with divert points that push or slide products onto takeaway spurs at programmed locations.

Types of Linear Sorters |

Common Use |

Throughput |

Item Type |

|

Sliding Shoe |

Distribution, Retail |

High |

Cases, totes, large parcels |

|

Narrow Belt |

Distribution, E-commerce |

Medium-High |

Cases, totes |

|

Pop-Up Wheel |

Distribution, Manufacturing |

Medium |

Cases, totes (flat bottoms) |

|

Pusher Arm |

Manufacturing, End-of-Line |

Low |

Robust cases, totes |

Sliding shoe sorters use a slat conveyor where small "shoes" sit between the slats. These shoes normally stay flush with the conveyor surface, but when an item needs to divert, multiple shoes slide diagonally across the conveyor path. This simultaneous sliding action pushes the product at an angle onto a takeaway spur. Line speeds reach 400-600+ feet per minute, processing 8,000-16,000+ cartons per hour with good accuracy for cartons and totes.

Narrow belt sorters run multiple thin conveyor belts side by side. To divert an item, the system changes the speed of adjacent belts, creating a speed differential that steers products toward their destination lane. This approach offers gentler handling than mechanical pushers because there's no physical impact, just differential belt speeds guiding the product across. They handle cases and totes at medium-high throughput rates.

Pop-up wheel sorters embed wheels into the conveyor belt surface. Normally the wheels stay down and items travel straight. When diversion is needed, the wheels pop up through the belt surface and spin at an angle, steering products onto takeaway conveyors. This makes them the lowest-cost automated option with simple integration into existing systems, handling 1,500-6,000 units per hour. Items need relatively flat bottoms for the wheels to make reliable contact.

Pusher arm sorters use mechanical arms positioned along the conveyor side. When an item reaches its divert point, an arm extends quickly across the conveyor width, physically pushing the product onto a takeaway lane. The direct mechanical action works well with heavy, robust cases and totes in manufacturing and end-of-line applications. Throughput is lower than other linear options but the simple mechanical design offers reliability for demanding environments.

Linear sorters are fixed infrastructure requiring 8-12 months for implementation with investments from $750,000-$4 million. They fit facilities better than loops in many cases since straight runs with spurs work with existing layouts. Implementation is faster than loop sorters and expansion happens by extending sorter length or adding parallel lanes.

Best for: Operations processing 5,000-15,000 units per hour, facilities with linear layouts or space constraints preventing circular systems, distribution centers focused on carton and tote sortation, and budgets in the $1-4 million range for moderate-to-high volume applications.

Challenges: Limited to cartons and totes, difficult to scale, and requires fixed infrastructure that can limit the ability to reconfigure and scale the system.

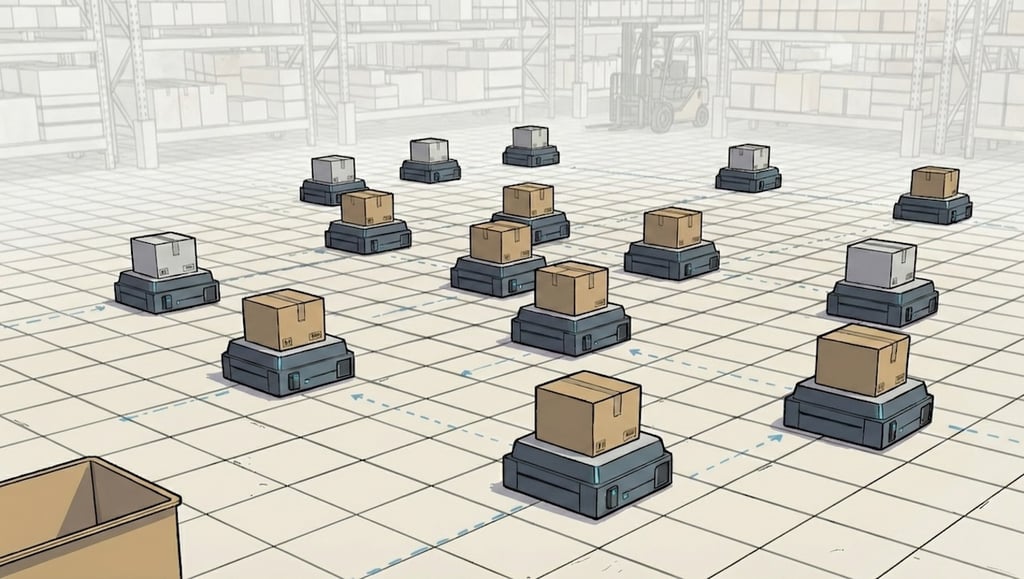

Autonomous Mobile Robot (AMR) Sorters: Flexible & Modular

Types of AMR-based Sorters |

Common Use |

Throughput |

Item Type |

|

Tote-based |

E-commerce, Distribution, Omnichannel |

Scalable |

Totes, cases, individual items |

|

Tray-top |

E-commerce, Parcel, Returns |

Scalable |

Wide mix, polybags, individual items |

|

Puck sorter |

Manufacturing, Pharmaceuticals |

Scalable |

Small items, apparel, polybags |

AMR-based sortation flips the model. Autonomous mobile robots equipped with tilt trays or crossbelts navigate freely using sensors, creating software-defined destinations that you can reconfigure in hours rather than months. No fixed paths. No predetermined routes. These systems can operate as standalone sortation solutions or be integrated seamlessly as part of a broader automation ecosystem such as downstream of a goods-to-person system or upstream of packing and shipping stations.

The throughput model looks different too. Full fleet deployments reach 40,000 units per hour while building in resilience that fixed systems can't match. When one robot goes down, the rest keep working. You scale by adding more robots, not by overhauling infrastructure.

Space efficiency comes from what you don't need. No elevated structures. No extensive conveyor networks. This results in AMR systems often requiring 25-75% less floor space than traditional sorters. Nothing bolts to your floors, which means you can relocate the entire system overnight if you move facilities. Implementation takes 5-7 months instead of 12-18 months because there's no structural work required.

The financial model shifts too. Capital investment starts 40-50% below fixed sorters because you're buying the robots you need now, not committing to five-year capacity projections that may not materialize. The goods-to-person approach reduces labor requirements further by eliminating walking time and bringing work to stationary operators. You can finance traditionally, lease, or use Robotics-as-a-Service models that convert capital expenses to operating expenses.

Best for: Operations processing 5,000-100,000 units per day with seasonal fluctuation creating 2-3x volume swings, growth uncertainty making five-year projections unreliable, facilities with limited ceiling height or irregular layouts, expensive urban real estate where space efficiency matters, and faster implementation timelines responding to competitive pressure.

Challenges: Typically do not handle very large or exceptionally heavy items well.

Sorter Type Comparison

| Sorter Type |

Product Mix |

Throughput Range |

Destination Count Range |

Scalability & Flexibility |

Investment & ROI |

Implementation Time |

Space Utilization |

|---|---|---|---|---|---|---|---|

| Tilt Tray | |||||||

| Cross-Belt | |||||||

| Bomb Bay | |||||||

| Pouch Sorter | |||||||

| Sliding Shoe | |||||||

| Conveyor Based Pop-Up Wheel / Pusher Arm |

|||||||

| AMR BOT tSort | |||||||

| AMR BOT tSortPost |

Choosing the Right Sorter

Start with your volume pattern. Steady year-round demand at 8,000+ units per hour favors loop sorters with the best per-unit economics. Linear sorters work well for 5,000-15,000 units per hour with moderate seasonal variation and 200 destinations or less. Robotic sortation handles 5,000-40,000 units per hour with significant seasonal swings and 200 to 10,000 destinations. AMR sorters (tSort) are great for high volume and higher destinations (200+). tSort is a winner for 2000+ UPH and 400+ destinations. Conveyor and tSortPost can manage applications with lower volume and lower destinations.

Look at your facility. Open floor plans suit loop sorters. Linear layouts favor sliding shoe systems. Limited ceiling height, irregular layouts, or plans to relocate point toward robotic sortation.

Evaluate your growth certainty. Confident three-to-five year projections justify fixed infrastructure investment. Uncertain trajectories argue for robotic systems that scale incrementally.

Factor in capital and timeline. Loop and linear sorters need $2-10 million and 8-18 months. Robotic sortation starts at 40-50% lower investment and deploys in 5-7 months

tSort and tSortPost: Purpose-Built AMR Sortation

Conveyor-based sorters—whether loop or linear—excel at handling steady, predictable volumes, but they lock facilities into specific layouts and long-term capacity assumptions. When product mixes shift or demand spikes unexpectedly, these fixed systems can become limiting. Tompkins Robotics addresses this gap with sortation solutions that provide you with the optimal mix of flexible, simple, and powerful performance for your unique operational needs.

At the core of our offerings is tSort, a modular sortation system that can sort up 40,000 items to 6,000+ destinations per hour including totes, cartons, mailbags, or gaylords. Whether square, round, or bagged, tSort is uniquely designed to handle just about any product type. Typically one-third the size of traditional sorters and without fixed infrastructure like conveyance, tSort can be deployed within just a few months and quickly scaled to match your business' growth.

tSortPost is an autonomous mobile robot built to sort a wide variety of containers across diverse workflows and order volumes. As a standalone solution, it can move and sort goods like flats, polybags, mail pieces, totes, and cartons freely throughout your facility—no need for heavy fixed infrastructure like conveyors or hard-wired electrical systems. That means fewer permits, lower costs, and a system that can be up and running in just a few weeks.

Both systems share the same operational advantage: you scale by adding robots, not by overhauling infrastructure. tSort scales through fleet expansion for high-volume centralized sortation. tSortPost scales through distributed deployment for flexible, zone-based sorting. Neither requires fixed conveyors, structural modifications, or facility downtime to expand.

Making Your Choice

The sortation landscape has evolved beyond simple automation versus manual decisions. You're choosing between three architectural approaches, each with different economics at different scales.

Loop sorters deliver superior value for high-volume operations with consistent demand and facilities built to accommodate circular configurations. Linear sorters balance throughput and investment for mid-range volumes in facilities with straight-line layouts. AMR-based sortation like tSort and tSortPost provides the best risk-adjusted returns for operations facing uncertainty, seasonal variation, space constraints, or capital limitations.

The question isn't which technology is better. It's which architecture aligns with your operational reality.

See how major retailers and 3PLs deploy robotic sortation. CVS and Komar utilize tSort to handle millions of units across store replenishment and omnichannel fulfillment.

FAQs

A: You're ready when you're processing 2,500+ units per hour consistently and labor costs or accuracy issues are impacting your bottom line. Below this threshold, manual methods with basic technology assists usually make more sense financially. However, tSortPost may be a great option for operations below this threshold.

A: Fixed sorters take 12-18 months from purchase to operation because of design, permitting, and installation requirements. Modular systems go live in 5-7 months since they don't require structural changes or extensive facility modifications.

A: This depends on your volume consistency. Fixed systems sized for peaks sit idle during slow periods, wasting capital. Modular systems let you add capacity temporarily during peaks, so you only pay for what you need year-round.

A: Plan for implementation costs (installation, integration, training), ongoing maintenance at 2-5% of capital cost annually, and potential facility modifications. Modular systems typically have lower total cost since they don't require structural work or extensive conveyors.

A: Start with a pilot zone to validate performance and train your team before expanding. Modular systems work well for phased rollouts since you can add capacity gradually. Most operations see the transition take 3-6 months from pilot to full deployment.

A: Modular systems adapt through software reconfiguration and adding or removing robots as needed. Fixed infrastructure requires expensive retrofits or replacement if your product mix, facility, or throughput needs change significantly.

Ready to see how modern sortation infrastructure can handle your distribution complexity?

Tompkins Robotics

Tompkins Robotics